Transforming Industries with Cutting-Edge Automation

Industrial Automation Solutions

At Unartech Solutions, we specialize in delivering custom industrial automation solutions that enhance efficiency, precision, and productivity. Our expertise spans across robotics, embedded systems, and IIoT, ensuring that businesses stay ahead in an increasingly automated world.

e provide end-to-end automation solutions, including robotic control systems, industrial IoT (IIoT), PLC integration, AI-driven automation, and vision-based defect detection. With our background in mechatronics, embedded systems, and software development, we bridge the gap between hardware and software to create reliable automation systems.

Our Industrial Automation Projects

We have successfully delivered automation solutions for multiple industries, including manufacturing, automotive, and industrial robotics. Some of our notable projects include:

🔹 ROS-Based Control System for Industrial Robotic Arm

We developed a robotic control system using ROS for Spotless AI Ltd. The system enabled precise automation for an industrial robotic arm, optimizing workflow and increasing accuracy in operations.

🔹 IIoT Monitoring System for Air Filter Production Testing

For Trident Pneumatics, we implemented an IIoT-based real-time monitoring system that streamlined air filter production testing, improving data accuracy and reducing downtime. We are currently working on a distilled database solution to enhance the system’s performance.

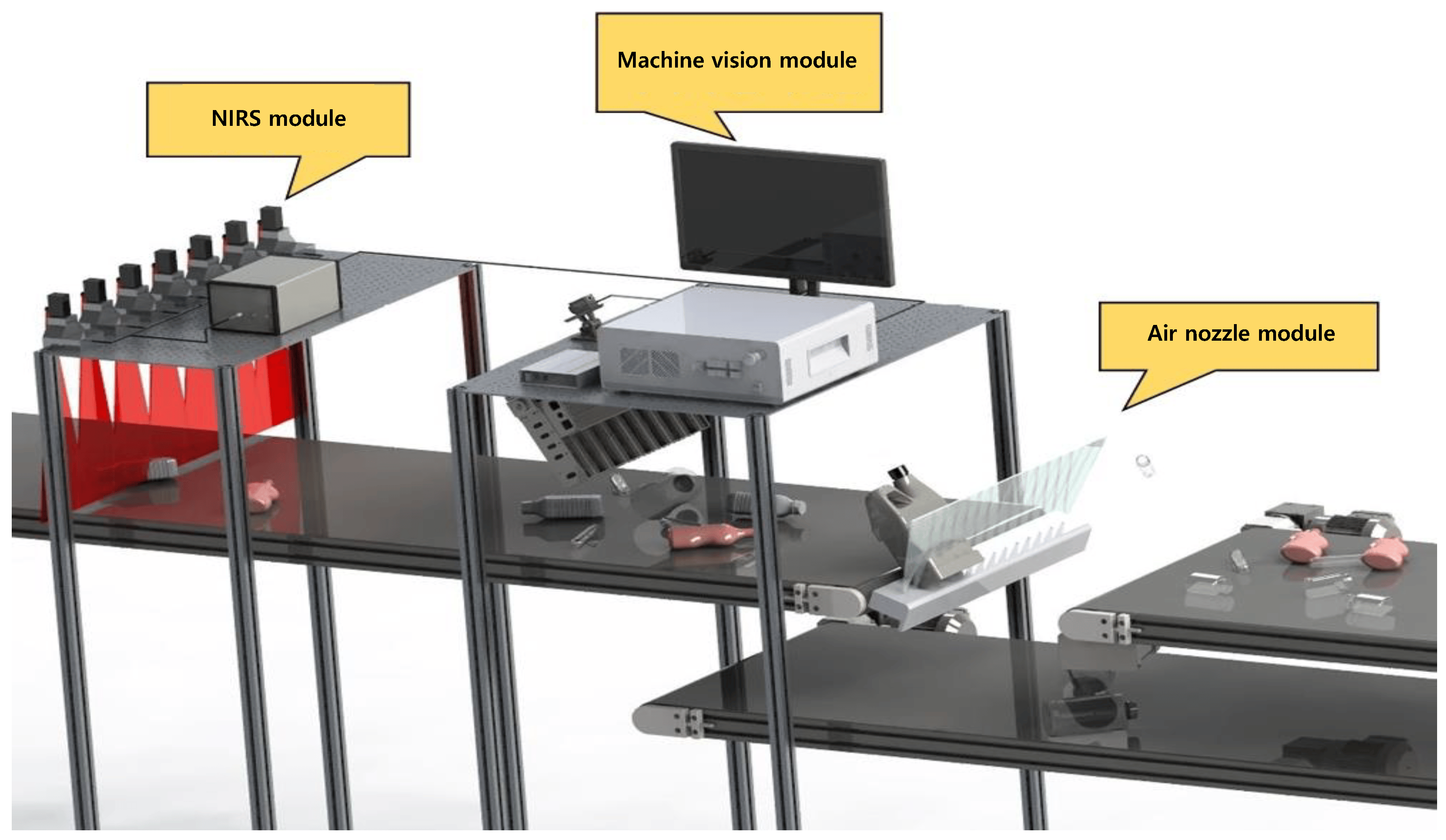

🔹 Computer Vision-Based Defect Detection System

Using AI-driven computer vision, we built an automated defect detection system for Skillwave, ensuring high-precision quality control in manufacturing.

🔹 PLC-Based Automation for Manufacturing Lines

We have experience in PLC programming and industrial control systems, enabling seamless automation of production lines for improved output and reduced manual intervention.

Why Choose Unartech Solutions for Industrial Automation?

✔ Customized Solutions – We tailor automation systems to fit your specific industry needs.

✔ Expertise in Robotics & Embedded Systems – Our team has hands-on experience in STM32, ESP32, ROS, and industrial automation protocols.

✔ AI & Vision-Based Automation – We integrate machine learning and computer vision for smart defect detection and process optimization.

✔ IIoT & Cloud Integration – Real-time monitoring and data-driven insights help businesses make informed decisions.

✔ Scalable & Future-Ready Systems – Our automation solutions are designed to grow with your business.

Our Industrial Automation Process

1. Discovery & Needs Assessment

We begin with a thorough analysis of your current operations, pain points, and automation goals. Our team conducts on-site visits, interviews key stakeholders, and documents your specific requirements to create a foundation for a tailored automation solution.

2. Solution Design & Planning

Based on our assessment, we develop a comprehensive automation strategy with detailed technical specifications, implementation timeline, and expected ROI. We present multiple approaches and collaborate with your team to refine the ideal solution that aligns with your budget and objectives.

3. Prototype Development & Testing

Before full implementation, we create a scaled prototype or proof of concept to validate our approach. This allows us to demonstrate functionality, gather feedback, and make necessary adjustments to ensure the final solution meets all requirements.

4. Implementation & Integration

Our technical team handles the full deployment of your automation solution, including hardware installation, software configuration, and seamless integration with your existing systems. We follow strict quality control measures and industry best practices throughout implementation.

5. Training & Knowledge Transfer

We provide comprehensive training to your staff on operating and maintaining the new automation systems. Our documentation and hands-on sessions ensure your team has the knowledge and confidence to maximize the benefits of your automation investment.

6. Monitoring & Optimization

After deployment, we continuously monitor system performance and collect operational data for analysis. We identify opportunities for optimization and implement refinements to enhance efficiency, accuracy, and productivity over time.

7. Ongoing Support & Maintenance

Our relationship continues beyond implementation with responsive technical support, scheduled maintenance, and system updates. We offer flexible support packages to ensure your automation systems remain reliable and effective for years to come.